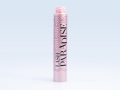

EMBOSSED UV LED SCREEN PRINTING ON PLASTIC MASCARA

Lancôme Mascara Monsieur Big

no images were found

Processing: transparent embossed screen printing with logo on cap and plastic container with an incredible tactile and visual effect.Issue: Only one printing technique – UV LED screen printing – granted the quality and resistance required by the L’Oréal company for approval.

So far, we had never ventured that far with UV LED screen-printing and, generally, you get embossed screen-printing with inks that swell or other techniques that would have never granted the printing quality required by L’Oréal. In the beginning, the biggest risk was to not be able to get the definition required by the logo; the presence of text and straight lines printed on a curved surface was a big issue, especially because the final effect should be embossed.

Solution: We designed a new screen printing application based on deposit and drying of large quantities of a special ink, by means of cutting-edge UV LED lamps.

Development: an application of this kind, that creates an incredible tactile and visual effect, immediately aroused great interest, and lead to several new requests, some of which less complex, as those that you can see in our gallery, but we had an immediate positive feedback.

We already had the opportunity to apply this technique to other materials like metal and glass.

For example, we can add special effects on the metal (you can see the pictures in the gallery of the product in golden color and milled effect), that are generally made using a specially created mold that mills the metal at much higher costs.

As for glass, creating a transparent thickness of the logo allows to avoid further costs due to the creation of specific molds.

The true sense of innovation is just that: the final output doesn’t look like a screen printing.

With this technique, you can reach the same levels of other processing technique with much higher costs; this can be very useful with small batches, that cannot afford custom-made molds, or, in the opposite case, with big batches, since you can have a custom-made primary packaging, at a lower cost.

All of this with a guarantee of resistance and approval, in compliance with strict specifications, as for the well-known L’Oréal brand.