Quality

INDECO represents corporate culture, customer care, speed of service, and a

guarantee of total quality.

OUR BUSINESS CULTURE.

INDECO Serigrafia: nowadays the quality of products and services is a prerequisite, a customer’s fundamental right. It is a simple, tangible fact yet complex if it is not encoded in the industrial process with detailed procedures that ensure strict controls. Conforming to the UNI EN ISO 2859-1 standard has shaped the quality culture that distinguishes INDECO Serigrafia.

TAKING CARE OF THE CUSTOMER.

With INDECO Serigrafia’s quality assurance process, the customer has a central role and can be informed in real time where its merchandise is located or how many pieces have already been produced. The Customer has access to all the relating documentation and can participate in audits and attend the range boards interfacing its auditor with INDECO’s quality control. A culture, that of quality, which creates reliable and, therefore, lasting partnerships.

SPEED OF SERVICE.

The Customer’s active participation in the company is supported by the internal technical departments which carry out the required corrections in real time, thus reducing production time and costs. Graphics, films and frames are produced in-house to ensure, from the beginning, the best production process and the highest customer satisfaction.

QUALITY ASSURANCE.

| – Checking incoming goods

– Original packaging integrity – Artwork checking – Checking printable areas – Colour alignment – Colour fastness |

– Checking piece/print deformations

– Production monitoring – Constant colour yield – Operator’s visual inspection – “GTI-MM1-MM2 grey camera” control – Checking outgoing goods |

A good quality control is in the quality of a good control

Strict entry and exit controls and a production process constantly monitored are the basis of the quality guaranteed by INDECO.

Visual rendering, centering, chromatic correspondence and endurance are the main checks carried out by our specialized technicians.

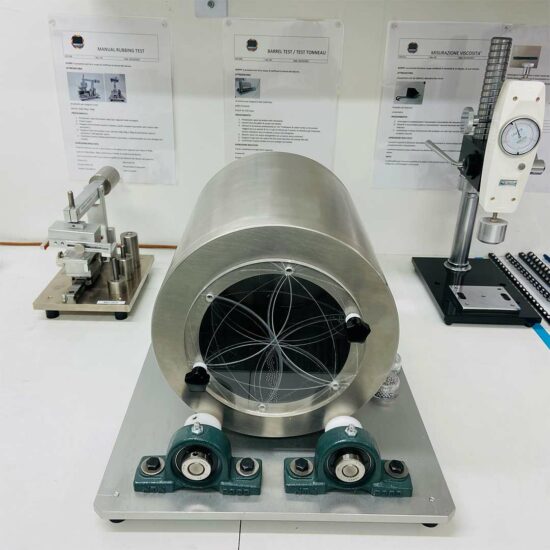

Knowledge of materials, expertise and high-tech equipment are instead the tools that ensure an excellent, constant yield of our end product.

Attrezzature per il controllo di qualità in laboratorio

I test che effettuiamo nel nostro laboratorio:

|

|

All of this is part of our project “INDECO Total Quality.”

We can help you if you have any question or need a quote or design requirement.